2022 Aug 31 Meat Birds Post Mortem

Year 1 running birds for meat; what went well, what didn't go so well, what will we do differently next year

What Went Well

Purchase

The chicks were purchased at Stromberg's. Price per bird delivered was $2.252 per bird for 100 birds, they actually delivered 104, accounting for some loss in transit, which we did not suffer. The White Plymouth Rock were in two sections of the four, and the New Hampshire chicks in the other two sections. No food or water, just a bit of bedding. Packages were delivered to the Post Office, just like bees.

Brooders

We used three 100 gallon stock tanks as brooders. Store-bought waterers, feeders, and 250W heat lamps for each. We used wood chips we had made from chipping branches as part of pasture reclamation. We lost no birds in the brooders over the course of the birds' ~3 week stay. Brooders were covered with chicken wire, and sometimes towels to retain warmth. Each brooder held ~35 birds. We had the brooders in the north side of the Sugar House.

Broiler Shelters, aka Chicken Tractors

After the first night there were no losses due to predation in the Shelters. Food trays were refilled 2x daily; water every 1-2 days. Moving was best handled by two people, especially at the outset when the chickens were smaller, and susceptible to being "run over." Waterers worked well once adjustment was sorted out. The tractors were built to 6 ft. 6 in. wide so they would fit inside the fenders of the 16 ft utility trailer. The tractors were 12 ft. long. Original design of the Shelters was 10 ft. wide by 12 ft. long, and from Joel Salatin's Polyface Designs book.

Transport

The only thing that went well regarding transport was that the Shelters fit between the fenders of the utility trailer.

Processing

The birds were butchered by Smokin' Butcher. Turnaround was fast, I dropped off on a Thursday evening and picked up on the following Saturday morning. Cost was $4.50/bird; we paid an additional $1/bird to have all of the livers, hearts and gizzards bagged up for us.

What Didn't Go Well

Purchase

With government intervention in food production, this year related to large culls of birds allegedly infected with the "bird flu," availability of birds might be a problem in the future.

Brooders

As chicks the feeders pictured were no problem, but as they get bigger they walk and shit on the feeders.

Two foot wide chicken wire is just barely wide enough to cover the width of the stock tank; this and its stiffness makes it more difficult to maneuver and secure, which might negatively impact protection of the chicks from predation.

Dust in the Sugar House makes work in cleanup.

Broiler Shelters, aka Chicken Tractors

The original chicken wire was too "loose" in its weave, which allowed birds to escape, wherein they were attacked and killed in large numbers (~40); the original chicken wire had openings of 2 inches by 3.5 inches.

Feeders posed the same problem as in the brooders, the chickens are walking and shitting on them.

Feeders too small; 2x daily feeding is too often, and the feeders were almost always empty, which implies the chickens were not getting their fill.

Because of the two person requirement, Shelters were not moved daily; this is a problem of both damage to the landscape and less robust nutrition.

We ran the chickens in the yard, which made access to bulk food and water easier. As the Shelters are placed further afield access to bulk food and water will need to be accounted for.

Transport

Getting the chickens out of the Shelters is a real problem. I had to literally crawl into the back half of the tractor to catch chickens, first when consolidating the chickens into one tractor, and a second time when transferring the chickens to the butchers containment. This was no fun.

We fashioned a "floor" for one of the Shelters, hauled the Shelter onto the floor, strapped the floor to the Shelter, and then pulled and pushed (with the Kubota) the Shelter onto the trailer. Also no fun.

Processing

I didn't like the look of the chickens as packaged for the customer. Chicken legs should be tucked up against the body, as seen when buying store chickens. Also, the vacuum bag used was a flat bag, which again does not result in the presentation I'm looking for.

Cost was $4.50/bird, and that was without the giblets. Seems high, but as of now I have nothing with which to compare the price.

Process Changes Possible

Purchase

In a SHTF (Shit Hits The Fan) scenario we could hatch out birds from the laying flock for our personal consumption. And with just a 21-day gestation period it wouldn't take long to scale up both the layer flock and meat bird production for sale or barter.

Brooders

Use hanging feeders instead of the galvanized trays, and hanging waterers; as the chicks grow the feeders and waterers can be lifted as necessary

Use a wider and more flexible roll of chicken wire; 30 inches wide would be perfect

Locate in the barn or other sheltered area where clean up is less of an issue, or no issue

Broiler Shelters, aka Chicken Tractors

Chicken wire has already been overlay-ed with a tighter weave, 1/2 inch by 7/8ths inch; this prevented predation problems

As with the brooders, use hanging feeders, which can also have the benefit of holding more feed

Access to bulk food and water: At the scale of only 2 shelters a barrel (~185 lbs) of feed lasts several days, and can be placed using the Kubota near the Shelters. Likewise, a 30 gallon barrel of water would last close to a week, and water could be dipped out with a 3 gallon bucket to fill the 5 gallon buckets on the Shelters.

Transport

As to getting the chickens out of the Shelters, Salatin says on page 3 of Polyface Designs, "Amazingly, many people get stuck on "how do you get them out?" <that'd be me> We simply use two pieces of quarter inch plywood, like a paddle, and bring the chickens around to the front, then slip the other panel in to close off the capped rear, putting a prop stick behind. This partition keeps all the birds in the front of the shelter." I have a design in my head; unfortunately drawings of the "paddle" are not included in the book.

Transport container: We used the Shelter/floor combination, which worked but was not close to ideal. One option, again at this scale, would be to build a third Broiler Shelter, but instead of having the two rear top panels secured to the frame, and covered with roofing material, have them covered with chicken wire and removable. Then, the frame could be loaded on the trailer, three of four cover panels put in place, and the chickens loaded through the fourth opening. Put the fourth cover panel on, secure the works to the trailer with ratchet straps, and hit the road. The "paddles" would be required for unloading at the butcher.

Processing

The chickens cannot be in rigor when packaged. The chickens need to "rest" after processing in a refrigerator or ice bath, for at least one day and possibly two before rigor passes and they are frozen. This is of course the responsibility of whoever is doing the processing. See the Backyard Chickens thread for more info.

Check into the availability of purpose-built freezer/vacuum bags.

Have the giblets packaged with each bird, this adds ~3.35 oz to each package; more food and more nutrition for the customer. Cost is an additional $1/bird at Smokin' Butcher.

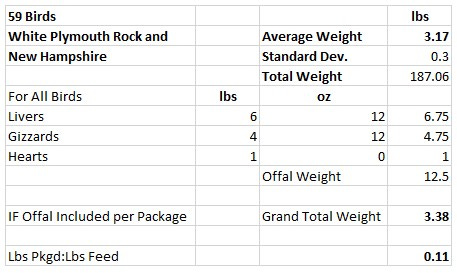

Summary Statistics:

Additional Notes:

I would like the birds to have been 4-5 lbs as packaged, and with the heart, liver and gizzard (not the neck), we would have been at 3.38 lbs/bird this year. A lot of this has to do with the breed, and we will probably experiment with the Cornish Cross, birds that should put on more weight, and faster.

One important metric is how much feed an animal converts to saleable weight. In this case, for every pound of feed fed, we had 0.11 lbs of processed bird to sell or consume. To put that in perspective, last year the pigs feed:saleable weight ratio was 0.17, so the chickens converted feed to food at a rate about 30% lower than the pigs.

To make matters worse, chicken feed runs about $0.36/lb, while pig feed is currently at approximately $0.23/lb, another 30% kick in the gonads for the chickens.

Having made the Process Changes outlined above we will give this another try in 2023. I'm not at all dissatisfied at the dinner table, but if the math can't be made to work it's not a sustainable enterprise.

Remember, “the obstacle is the way,” or “the problem is the solution.” In other words, inside the “what didn’t go well” is the opportunity for improvement.

Rumble Videos:

2022 Apr 22 Meat Bird Experiment Day 1

2022 May 19 Chicken Move to Broiler Shelters

Great stuff John. Love the way you analyze to enhance. A great follow-on to the decision on next years syrup operation. You are doing well.

JB, Your adventure is motivating, and I find myself living vicariously through Geri & you!

Just a thought, could you cover the bottom of the tractors with the smaller chicken wire and then you would

1) be able to move them with the Kubota?

2) also possibly deter rats from burrowing under, which I have seen the results of (utter devastation in a single night).

3) could load on the trailer the same way

Might not allow them to scratch the soil as much but they can still peck the ground.

I have never done chickens on the scale that you are undertaking so, all this ‘free advice’ might be worth chicken shit😉