Maple Syrup Business Analysis 2020

Reflection is key to improvement planning

If you are interested in a little of the philosophy behind Primal Woods, our Purpose, and an introduction to how this maple syrup business analysis was put together, have a look at this video. I'm not saying that this is how you should do it, I'm only saying that this is how we do it. If you're only interested in the "how-to" of measuring and analyzing your business, skip the video and go straight to the details involved.

Maple Syrup Business – Measurements

I typically don't start from scratch; there's really no need to most often. Use the available resources. In the case of developing the Primal Woods plan for pure maple syrup business, I used a template from Les Ober at Ohio State University. If you're in the business of making maple syrup, Ober's blog is informative; he also maintains a Facebook page. For the latest published Maple Syrup Business Planning Guides, click here: OSU EXTENSION » GEAUGA COUNTY » PROGRAM AREAS » AGRICULTURE AND NATURAL RESOURCES » MAPLE PRODUCTION AND EVENTS. For the latest Bucket planning guide in particular, click on the next image.

Obviously the advantage of starting with a template is that I don't have to invent the financial statement. A disadvantage is that it can close your mind to other necessary elements. A good example is the use of energy in the maple syrup production process. In the template are oil or wood for firing the Evaporator, diesel and/or gasoline, and "utilities." At Primal Woods we use wood for firing the Evaporator, kersosene for warming the Sugar House pre-season, gasoline for the Polaris UTV and a Sap Transfer Pump, propane for some steps in the syrup finishing and bottling processes, and electricity. And lest I forget, feed for the horses! The biggest energy consumer is the Evaporator by far, but that doesn't mean the others are negligible, especially electricity. There's a blower on the Arch, a blower on the Steam Away (sap pre-heater), an electric air compressor powers the Filter Press, tank heaters are sometimes used to prevent sap from freezing, electric pumps for moving sap from Storage Tank to Head Tank, electric drills for tapping, and last and probably least, lighting. If you employ reverse osmosis (RO) to concentrate sap, electric use will definitely become significant. You get the point I'm sure; refine the template as necessary to suit your business.

A final point I'll make on the template is the "Equipment" section near the bottom. In real estate what Les has included there is what's called a "sinking fund." It's depreciation effectively, it's not cash out the door (after you've purchased the equipment), but it is a real cost nonetheless. "Stuff" has a useful life, and if your maple syrup business can't fund the maintenance, repair, and ultimately replacement of your stuff, you won't be a "going concern" for long. Be honest with yourself in the bookkeeping department.

Data Collection

To perform an analysis of the maple syrup business, data is required. Data, record-keeping, is one of those nasty little details that I'd venture to guess most small scale operators don't attend to. Here's a little bit about what goes into that at Primal Woods.

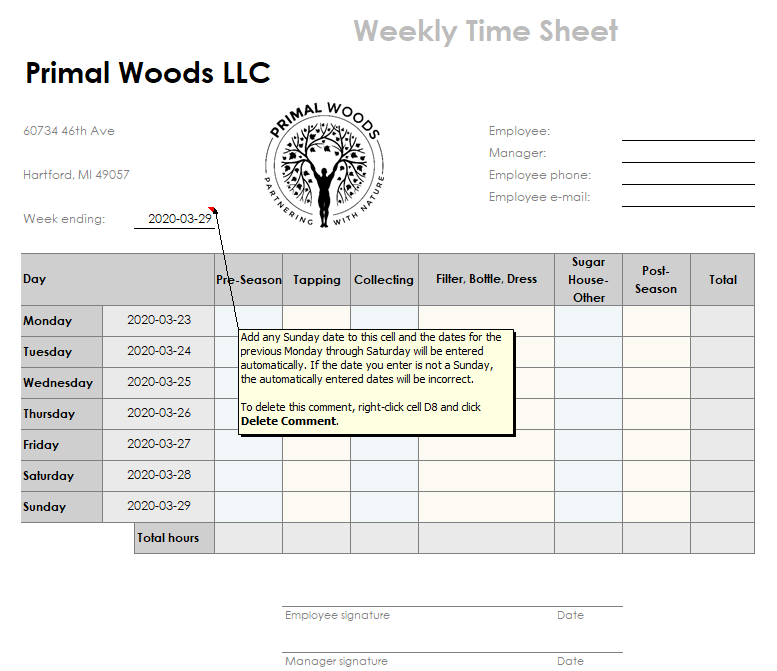

Labor

You'll notice we keep track by task, or activity, broken down into six major categories. Why so much detail? So that we can pin point where opportunities for improvement lie. This year for example, we spent a significant amount of labor hours in pre-season clean-up/set-up. Having changed our post-season process for the better this year, I think in 2021 the requirement for paid labor in the pre-season will have been virtually eliminated.

Utilities

For electricity, we had a separate meter installed for the Sugar House; it's not however on a separate account with the utility company. Pre- and Post-Season records are kept, the difference is recorded as our usage for the season; in this case we started Feb 04 and wrapped up Mar 30.

We use a similar method for other energy. For example with firewood, our stacks are 3 feet wide and 4 feet high, which means a cord stacked is 10 feet 8 inches long. I measure how many feet of stack we consumed, and divide by 10.67. This year we used 4.25 cords. Kerosene is managed by 2.5 gallon containers, gasoline in 5 gallon cans, etc. For propane, record the tank level as a percentage before and after, subtract the latter from the former and multiply by tank capacity. Hay for the horses, same drill, bales before minus bales remaining equals bales consumed. Once you know how much you used simply multiply by your cost/unit and there you have it.

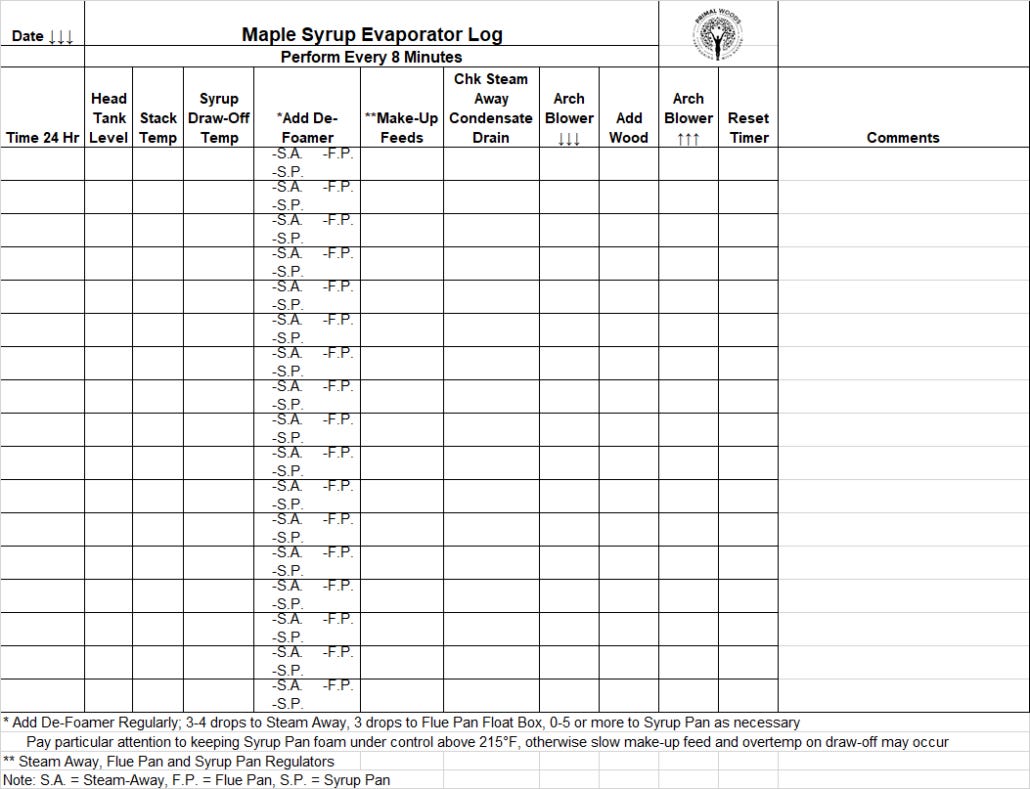

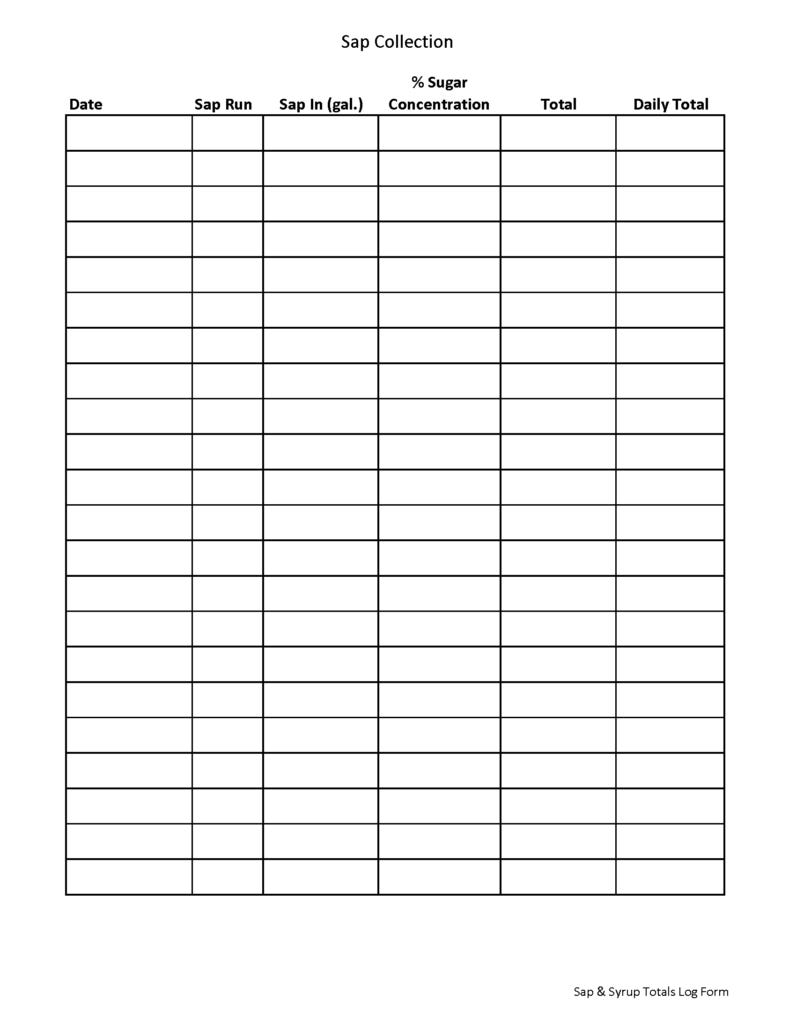

Production

It terms of sheer weight, the Evaporator Log is the winner. Every 8 minutes various checks are performed. This is a great way to help in fully understanding how well the Evaporator is performing, what is working well, and what's not working so well. Like all of our processes, forms and job aids, this log is continuously revised as improvements are developed.

Sap collection and Syrup production records are also maintained. In combination with the Evaporator log I know how many days and hours I spent at the Evaporator, how much sap was evaporated, and how much syrup was produced. Gallons of sap to yield a gallon of syrup is one of the most oftened cited ratios in the maple syrup business. The "rule of thumb" is 43:1, that flows from the "Rule of 86," 86 divided by the percent sugar concentration in the sap (2% is the rule of thumb), equals gallons of sap required to produce gallons of syrup. If, as happened this year, the sugar concentration falls to 1.5% at year end, 57 gallons of sap are required to produce 1 gallon of syrup.

Maple Syrup Business – Analysis

Profit & Loss

So now what? So far we just have data, we have yet to develop any information, or knowledge, based on that data. Take the data you have collected, including the cost of any capital investments you have made, and complete the Ober "Planning Guide." You can do this on paper, or reach out to me at john@primalwoods.com and I will set up up with a spreadsheet that you can modify to suit yourself and your business. One thing I add is a column for expense as a percentage of sales. The bigger the expense, the more likely it is that you can find significant savings within that expense. In short, the Profit and Loss Statement is one of two key products of this analysis.

Problems & Opportunities

I always start with a process flow diagram as I explained in the video. It helps me to organize my thoughts around increasing the scale of our operation, and around improving the operation. Throughout the season I am recording problems, and successes, usually with pencil and paper. Make a point of consulting your workforce. This year for example, on one particular day I noticed that the troops came in very quickly after a round of collecting, and we had an instant stand-up meeting on the subject of what went well with collecting, and what we could do better. Lauren acted as scribe. This information allows us to incorporate what worked into our process documention, causing it to persist to our benefit, and to incorporate additional improvements in the future.

In the larger context, the whole of the maple syrup business, we put together a "reflection" document that is broken down into four categories; Problems Big and Small, What Worked Well, Ideas, and Useful Knowledge gained.

The "Reflection" is the second key product flowing from the analysis. This document will be used to prioritize problem solving efforts leading up to the 2021 season, incorporating what went well into our process documentation, and in exploring new ideas for strengthening the business.

Maple Syrup Business – Summary

Nobody said it was going to be easy. Making maple syrup is an energy and labor intensive business, especially when using buckets, horses, and people to the extent that we do. The choices we have made make our maple syrup more costly than that of the industrial-scale producers, but that doesn't mean that we should sit back and accept inefficiencies that can be eliminated, even within the context of our decidely "old school" operation.

If you've enjoyed this post, or value you what we are doing, I hope you will visit our Shop and give us a boost; it will be greatly appreciated I assure you. Comments and constructive criticism are also highly valued. If you want to improve your problem solving, leadership and management skills, the books below will be helpful.

All the best, and kind regards,

John

Earn rewards by referring friends!