Planning for 2018 Maple Syrup Expansion

Pure Maple Syrup process expansion; from hobby to business

It is is mid-June, and already I feel a bit late in putting together the improvements necessary to significantly scale up maple operations in 2018. This is my first pass at identifying what needs to be put in place to increase production by a factor of 8x to 10x. The number of taps will go from 50-70 in 2017, to 400-500 in 2018. What will stay the same, and what will change?

As to what will stay the same:

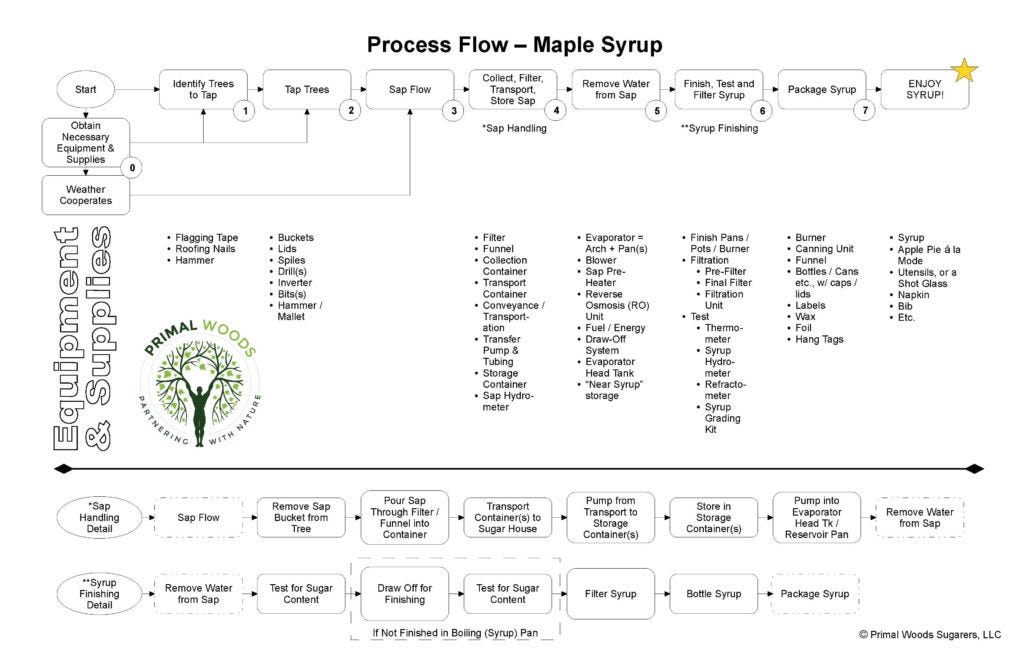

At a high level, the process will not change. I only made one change, and that was to add "Near Syrup Storage" under Step 5 Remove Water from Sap; that was more of an oversight in the original documentation of the process, than it is a change to the process.

We will stay with traditional taps and buckets for sap collection; we have no desire to take the involvement of our community out of the process, and, it is my firmly held belief, that when our customers buy maple syrup, they are buying something more than the maple syrup. They are buying too a taste of an earlier, simpler time, when neighbors were neighborly, and community provided support for family. Something like that; again, my words fall short. By design, it will not result in the lowest production cost; we have no intention of getting into a "race to the bottom" cost-wise. We will constantly check ourselves against "Our Purpose."

We will still use a wood-fired evaporator. The full-circle nature of the business, trees providing sap, dead trees and waste from the sawmill providing fuel to evaporate said sap, and ashes from the evaporator used to make lye for use in the soapmaking process, will be preserved.

We will still filter the syrup using only gravity to move the syrup through filtering media

We will use our Michigan source of supply for most if not all improvement needs, that being Sugar Bush Supplies in Mason, MI

While it's not a sure thing, it seems highly likely that we will use Leader Evaporator as the manufacturer of the new evaporator; their distributor is Sugar Bush Supplies, and they have provided nothing less than outstanding support to our efforts in 2016 and 2017.

We will still be outside when evaporating, which is to say, we will not be building a full-blown sugar house this year. We will be under a shelter similar to the 2016 and 2017 seasons, albeit a much larger shelter.

The list of what will change is significant, and represents the largest investment we have made in the business since the Wood-Mizer LT40HDG35 portable sawmill. Below is a list of improvements, based on the steps outlined in the Process Flow-Maple Syrup diagram, and the associated lists of equipment and supplies needed:

Step 1: Identify Trees to Tap (no improvements required)

Step 2: Tap Trees

At least two battery operated drills with bits and spare batteries

300-400 buckets & lids

300-400 spiles (aka taps)

1 helper

That last, "1 helper," is an improvement that I am really looking forward to. No longer will Geri and I be able to manage the process ourselves, we will need the help of people from our community. There will be no mistaking the scaled-up operation for a hobby.

Step 3: Sap Flow (God willing and the creek don't rise, we will be blessed with an awesome season)

Step 4: Collect, Filter, Transport and Store Sap

Filter/Funnel to screw into sap transport barrel bung (current filter/funnel does not fit the top of barrels properly, and is a pain in the ass)

New, clean, white 5 gal buckets to move sap from trees to barrels, qty 2

Assemble and test sap transfer pump and "system"

275 gal tote, qty 1, refurbished with new bottle

1-2 helper(s) (more help needed, yeah!)

Step 5: Remove Water from Sap

Evaporator Arch + Patriot Pans (capable of at least 40-50 gal per hour). From the Sugar Bush Supplies catalog: "Patriot Raised Flue Evaporators - The Patriot reverse flow evaporator has 7 ½” raised flues and features two float regulators—one to regulate incoming cold sap into the flue pan and another to regulate the flow of hot sap from the flue pan into the lower syrup pan. The dual floats allow the ultimate in liquid level control. The pans come in sizes ranging from 2’ x 6’ up to 6’ x 18’ and can be installed on any of Leader’s arch styles. And like other Leader evaporators, the Patriot is easily expanded with the addition of a Steam-Away or Reverse Osmosis." In my opinion, drop flues, like those in the Half Pint "Supreme" pan currently in use, hold concentrated sap, not allowing it to move along as it otherwise would to the draw-off; though it markedly increases the evaporation rate.

Inferno airtight arch plus Patriot raised flue pans, it's a beast

A second sap pump to move sap from storage tote(s) to the head tank

An enclosure (shelter) for the Arch + Pans and related equipment

Electricity for the arch blower and pump(s)

Sufficient DRY firewood

HELP in putting up sufficient dry fire wood (recurring theme, additional manpower needed)

Evaporator head tank needed, at 40 gallons per hour, in my opinion, especially since the Patriot includes a float to "regulate incoming cold sap in the flue pan

Draw-off system; "near syrup" drawn off of finishing/syrup pan. Figure 1 gph of "near syrup," aka concentrated sap, coming off of the evaporator.

"Near Syrup" Storage Containers. Could be 1 gal per hour for 10 hrs with average of 1 gal in each bucket that's 10 gal of "near syrup" per 10 hr day. On a heavy flow day, that could double to 20 gal per day. That latter number would fill four 5 gal stainless steel (SS, aka expensive) milk containers. Depending on whether or not I can keep up in the finishing process, or in the event of a multi-day run, I may need to be able to store 2 or 3 times that much.

Step 6: Finish, Test and Filter Syrup, Step 7: Package Syrup

2nd, back-up, syrup hydrometer; if the hydrometer breaks, I'm down until I can get a replacement, unless a back-up is on-hand

New "outdoor" finishing pans, see 2017 Sugar Bush Supplies catalog, "16” x 34” FINISHER This is the perfect finisher for the small volume producer. Stainless steel, tig-welded pan with 1” bottom-drain threaded fitting and 1/4” FPT fitting for dial thermometer (not included). Capacity 25 Gal"

New filtration unit, see catalog referenced above, "16” x 24” FILTER & CANNING UNIT The big brother to the 12” x 20” canner, this unit will heat and hold up to 15 gallons of syrup. Sturdy steel stand has adjustable legs for leveling, an adjustable canning shelf with built-in 40,000 BTU L.P. burner, valve, hose, and regulator (gas cylinder not included). Uses flat 24” x 30” pre– and final filters."

Bottles, cans

Labels

Hang tags

Shipping materials; boxes, tape, packing material, etc.

And that's it, really, nothing too overwhelming <wink>. Let's just say, there is a lot to do before winter sets in. If anyone sees anything I have overlooked or has an opposing point of view, please comment.

All the best, and kind regards,

John

Earn rewards by referring your friends!