Portable Sawmill Service Load-Out

Being prepared for any milling problem that can be anticipated

Preparing For Portable Sawmill Service Work

The key word here, is portable. Which is to say, you are some distance from the usual support systems of a typical stationary sawmill. You may not have access to your full suite of tools; on weekends technical support from the manufacturer of your portable sawmill may or may not be available. And as the Sawyer time is not on your side. Downtime is the enemy, and everything must be done to prevent it, and respond to it if Murphy shows up. So, what exactly does that entail?

Portable Sawmill Service Preparations - High Level

Knowledge: It certainly helps to have some experience dealing with mechanical and 12VDC electrical systems; no better learning platform in my opinion, than cars and trucks. If you have done your own maintenance and repair on cars and/or trucks, you are going to be a step ahead. Small engine repair experience wouldn't hurt.

Maintenance: Maintenance of the portable sawmill is not insignificant. In the case of a Wood-Mizer, you are looking at maintenance intervals of 8 hours, 25 hours, and 50 hours, regularly, plus some less frequent maintenance at 200, 500, 750 and 1,000 hours. My advice is, do it religiously. Wood-Mizer puts together a maintenance table for the portable sawmill "platform," I'll call it, but you will have to scan the manual sections regarding the engine, hydraulic system, de-barker, and any other options or accessories you have attached to the mill. I intend to do a separate post on maintenance of the portable sawmill, but suffice it to say for now, if you want to avoid breakdowns, and supply the highest quality lumber possible, in the least amount of time, maintenance is a necessity.

Portable Sawmill Service Job Preparations: This is the focus of this post. What do you do, and what do you bring with you, when going on a service call?

Portable Sawmill Service Job Preparations

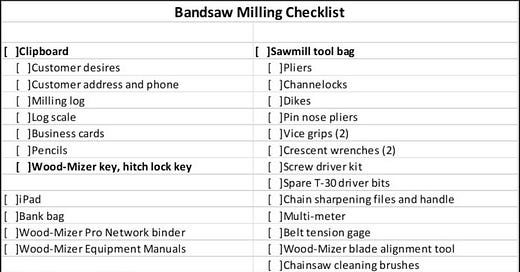

As stated in this blog before, I'm a List Guy. I'm sure this is a result of my Navy experience, and the Navy's Planned Maintenance System. I don't care how often a particular maintenance item had been done, you better have the MRC (Maintenance Requirement Card) with you, and in use, when you do it. Load-out for a portable sawmill service job is no exception to this rule. Below is my load-out checklist; I'll go down this step-by-step.

Clipboard: I carry a clipboard with me, with a built in compartment, and the clip incorporates a calculator; very nice. I have record of the customer's desires, on paper, in email, or in Evernote; accessible to me either in the clipboard, or on my smart phone or iPad. On blank milling logs I record details for each log milled, including the length and diameter of the small end of each log; I use this information primarily to record board feet milled (using the log scale), but I also record breaks, breakdowns, blade changes, fuel stops, etc. I bold the hitch lock and Wood-Mizer keys, because if I forget those the job is done before it's started.

The iPad and bank bag are for the financial transactions. The need for equipment manuals should be obvious at this point. Approximately 10 gallons of gas will get me through a full day of milling; I'll take more if necessary. Tow strap and logging chain, and cant hook and Peavy for moving logs. Chainsaw with 20 inch bar for taking off branches, trimming up big logs, etc. Blocking is odd bits of lumber, usually 2 by and 1 by material, for getting the log set up as I want it on the mill; blocking is used extensively when chainsaw milling, too. Blade lube additive cuts pine tar when milling conifers. Broom for cleaning sawdust off of the mill and the lumber. Mechanics toolset for maintenance and repairs. Extra blades; I go through 3 to 5 in the average full day.

Bucket: Various items mostly to support the chainsaw(s). The "outrigger tool/bar" is used to set the outriggers on the mill, stabilizing it. Forget this, and you might have some trouble; a jack handle will bend like a wet spaghetti noodle. The emory paper is for cleaning the rails and mast on the Wood-Mizer. Safety equipment, specifically safety glasses, gloves, and hearing protection.

Sawmill tool bag: You guessed it, tools to support portable sawmill and chainsaw maintenance and repair, together with the mechanics toolset. I have Wood-Mizer tech support on speed dial.

Consumables: ATF can be used as hydraulic fluid in the portable sawmill, and is used for lubrication of the mast, rails, and chains on the mill. Dielectric grease is used to lubricate rotary switches on the mill, and keeps the 7-pin trailer connector working, and hence the trailer lighting and electric brakes. Lag screws and nails are used in chainsaw milling.

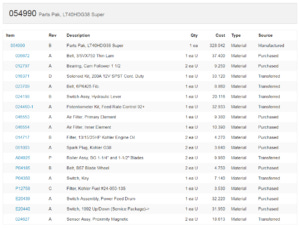

Spare parts tote: As the name implies, primarily for the storage of the Wood-Mizer "Parts Pak."

Spare ripping chain for the chainsaw mill, 2-stroke oil for mixing chainsaw gas.

Backpack: Contains this and that to support me.

Portable Sawmill Customer Service

It's all about serving the customer. Do I have breakdowns? Yes. But the customer clock stops until I recover from the breakdown, and I do everything I can to minimize the bringing of inconvenience to the customer. Also, the quality of the lumber, the accuracy of the cuts, is of great importance to me and the customer. As with any service I suppose, "word of mouth" is critical, and social media is a double-headed axe; it can cut to your benefit, or worse to your detriment.

I have a similar list for chainsaw milling, and in cases where I am doing both on a job, I print off and check off both lists when I'm loading-out the truck. Speaking of which, though beyond the scope of this post, maintenance and preparation of the tow vehicle is as important as the portable sawmill service preparations listed above.

Portable Sawmill Service - The Outcome

The point of process, is to reliably attain a particular outcome. Or at least that is one definition. When it goes "right," it results in days that will be long remembered by the customer. And by design and faithful execution then, it most often goes right.

Whether you are a Sawyer, or you are on the hunt for a portable sawmill service, I hope you have found this information useful. Please comment on the post either way! To engage me in a conversation regarding your milling needs, Contact Us.

All the best, and kind regards,

John